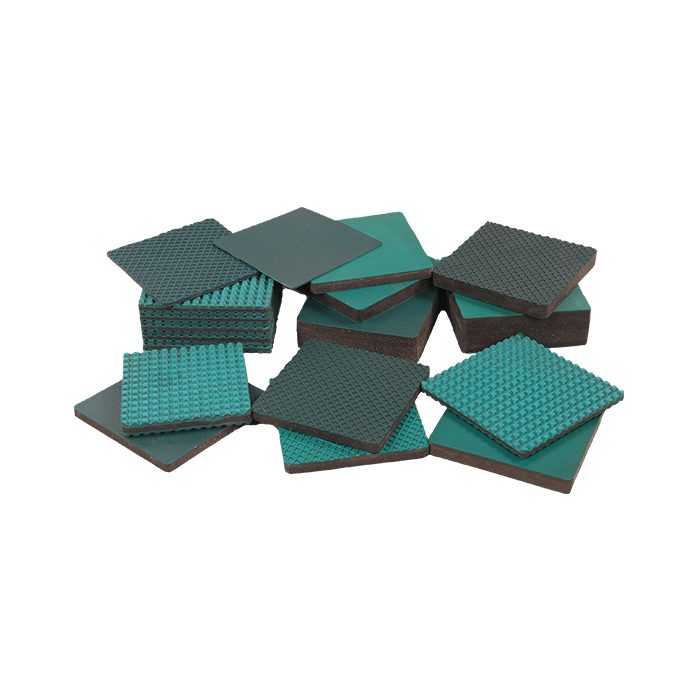

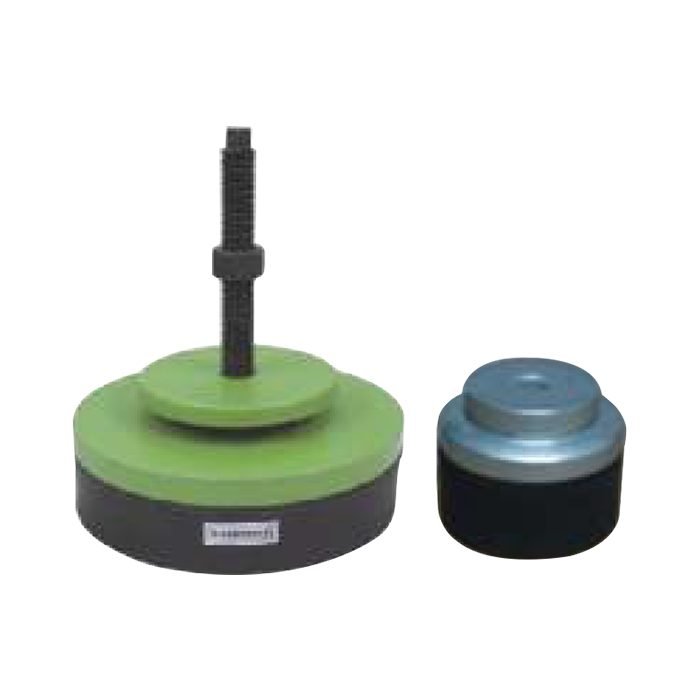

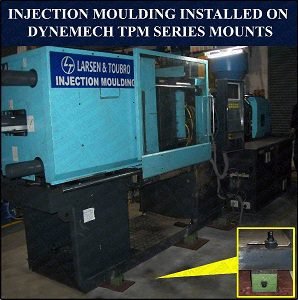

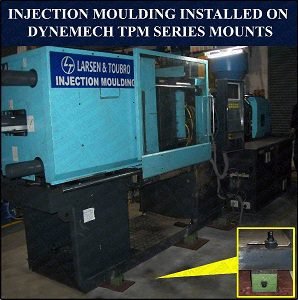

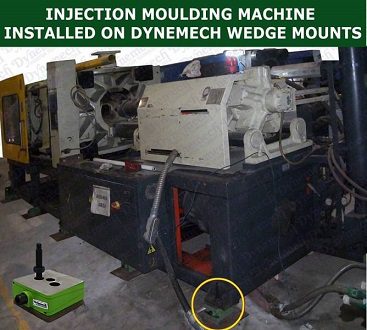

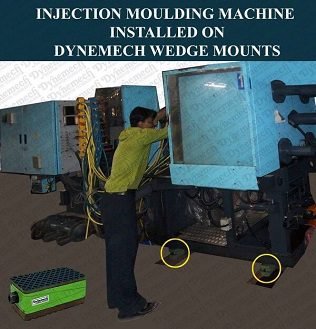

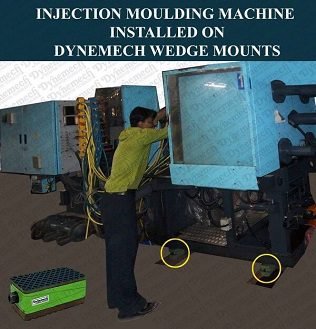

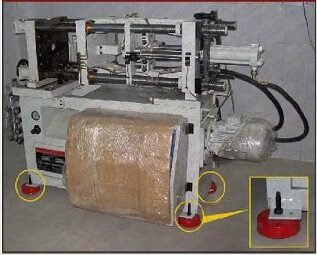

Dynemech’s Injection Molding Machine Mounts provide optimum leveling and alignment of the machines within minutes, without anchoring either the machine or machine mounts to the floor. Dynemech Insulation Sheets are designed especially for injection molding and die casting machines. These vibration insulation sheets dampen both vertical and horizontal impacts found in reciprocating machines. In addition, each vibration isolation pad is engineered to possess an exceptionally high coefficient of friction that also prevents machine “walking”.

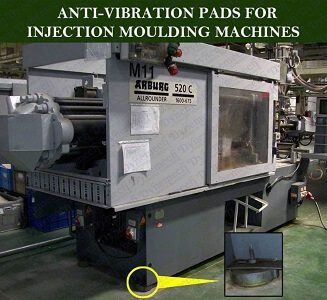

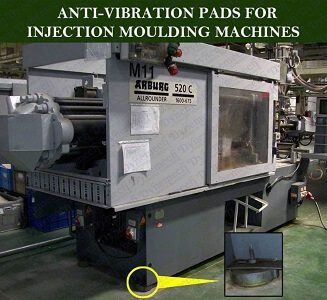

An Injection molding machine, also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. Injection molding machines can fasten the molds in either a horizontal or vertical position. The majority of machines are horizontally oriented, but vertical machines are used in some niche applications such as insert molding, allowing the machine to take advantage of gravity. The operations in Injection Moulding Machines produce high impact forces. These forces travel through the machine frame into the foundation. The foundation produces a rebound force equal to the impact force and this travels inside the machine. The magnitude of the vibration within the Injection moulding machine is lower when using Anti-vibration machine mounts. Bolting the machine rigidly to a foundation subjects it to more vibration and impact force. Vibration isolators or machine mounts are cushions that transform a sudden shock pulse into a decaying series of longer duration forces.

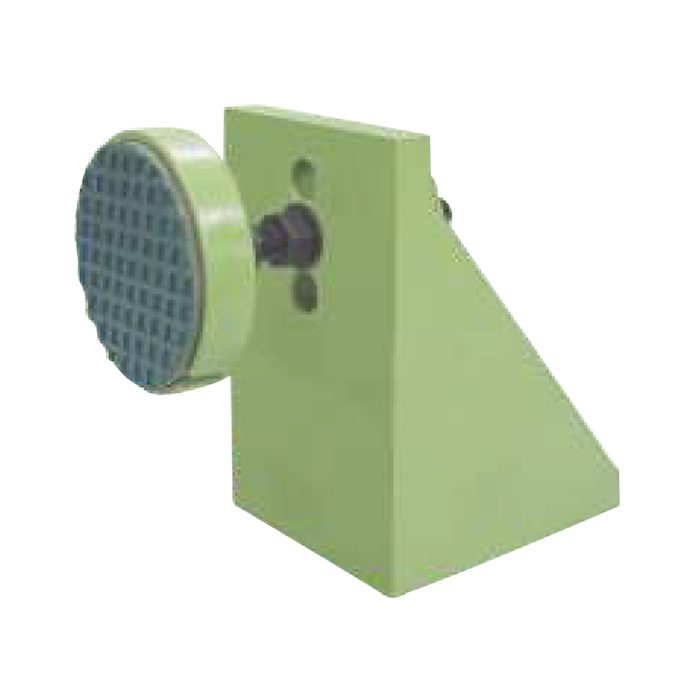

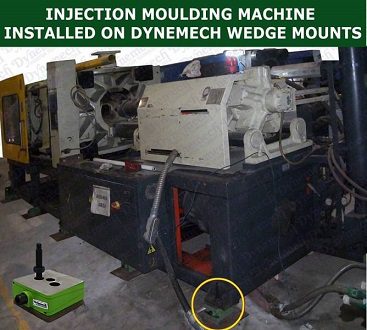

Injection moulding is a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. Material is fed into a heated barrel, mixed, and forced into a mould cavity where it cools and hardens to the configuration of the cavity. Injection moulding is widely used for manufacturing a variety of parts, from the smallest component to entire body panels of cars. To ensure higher productivity, better control, faster injection rates or better quality finished parts, Numerous automobile part manufacturers, Plastics makers, Toys makers, Aerospace, Manufacturers of Plastic Capsules and Health Related Equipments, Packing and Plumbing Equipments manufacturers turn to Dynemech range of flexible vibration control solutions ranging from DYNEMECH INSULATION PLATES, Die Cushion Pads, Wedge Mounts, Screw Support Mounts, Economical Mac Level Series DML, Series DLM/DLMS which help us to install machines even on uneven surfaces and the recently developed DLK series.

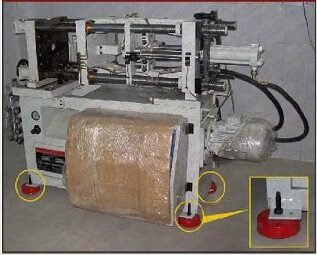

Fig 1: Injection Moulding Machine installed on Anti Vibration Machine Mounts

Dynemech Injection Moulding Machine Mounts with Elastomeric Pads offer many benefits:

1. Increased equipment life.

2. Installation Savings – Machines are installed faster and easier.

3. Simplified machine installation.

4. Precision Levelling and alignment of machine mounts reduces machine wear and tear & increases tool life

5. Machine “walking” prevented.

6. Different products/customized solutions available.

7. Reduced shock and vibration.

8. Simple integration into the production plant due to flexible installation.

9. Elimination of anchor bolts. Machine can be easily re-located and Re-Levelling is much faster and easier.

10. Better Structural Safety.

Dynemech is the leading manufacturer/exporter of Anti-Vibration Machine Mounts for all kinds of injection moulding machines. Dynemech’s engineering team provides complete guidance in proper pad selection for various different types of moulding machines depending on the machine specifications and external factors (like installation location). They provide detailed installation notes with illustrative diagrams for correct machine mounts installation.

Vibration Control in Injection Moulding Machines installed on Injection Moulding Machine Mounts

Injection Moulding Machine Mounts Vibration Damping and Leveling

Injection Moulding Machine Precision Levelling Wedges

Vibration-Damping-Mounts Injection-Moulding-Machines

DLK-Leveling-Machine-Mounts Injection-Moulding-Machines

Height-Raiser-AV-Mounts Injection-Moulding-Machines

Vibration-Isolation-Feet Injection-Moulding-Machines

Injection Moulding Machine Mounts – Vibration Damping through Isolation