Heavy-duty anti-vibration pads are indispensable in a variety of industries that use large machinery and equipment. These pads reduce the transfer of shocks and vibrations. Which ensures that the machinery runs smoothly while lowering noise and avoiding structural damage. Similar to technology, there are new trends emerging in this area as well. These pads used rubber or cork in the past as their material. This provided adequate vibration-absorbing facilities. However, there has been a noticeable advancement toward implementing variations that not only provide improved performance durability.

We’ll delve into the most current innovations and trends impacting the industry as we examine the future of these pads in this blog post.

Understanding :

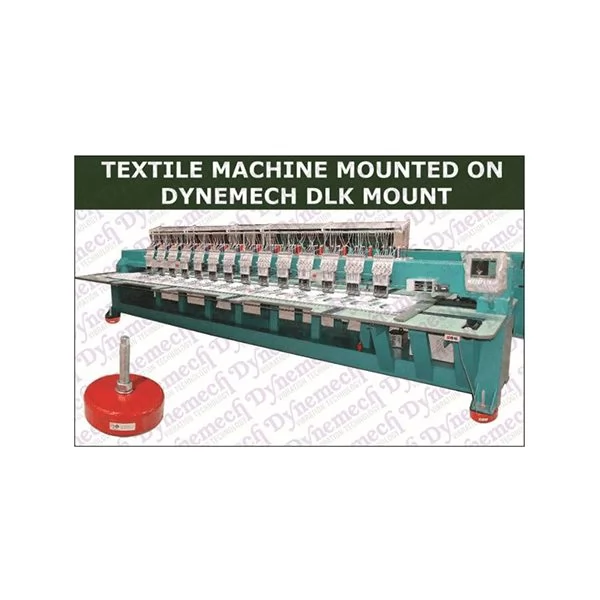

Heavy-duty anti-vibration pads are an essential component used in many sectors to cut down the effects of vibrations produced by large machinery and industrial units. These pads are of not only great utility but also reasonably quiet down machinery, guard against structural damage, and enhance the overall performance of the machine. The industries that require these are automotive, rail, and aerospace precisely industries of transportation. They are used to reduce vibrations in cars, trains, and airplanes to protect vital parts from accelerated wear and tear while also ensuring passenger comfort and safety.

Advancements in heavy-duty anti-vibration pads:

Innovations in technology have been the main reason behind the advancement in Anti Vibration Pads For Heavy Machines, whether it is a factor of looks or usability. These improvements have increased their ability to absorb vibrations, along with their toughness and adaptability to cater industry’s changing demands.

The following are significant developments in heavy-duty anti-vibration pads:

- Developments in Material Design: Advanced composite materials have replaced standard substances like rubber and cork.

- Enhanced Vibration Dampening Capabilities: Active damping technologies are the main reason behind the operational change. In real time, these systems actively combat vibrations by using sensors and actuators.

Sustainability and environmental consideration: Sustainability is an essential aspect of material technology advancements. To lessen their impact on the environment, manufacturers are creating eco-friendly materials and manufacturing techniques.

Conclusion:

The future of heavy-duty anti-vibration pads is commendable. Manufacturers are pushing the boundaries of innovation to fulfill these evolutionary needs in the industries. Striving for improved performance, sustainability, and adaptability has resulted in Advancements in anti-vibration pads, with the use of modern composites and high-density polyurethane. These materials have better absorption and dispersion qualities, resulting in improved longevity and more effective vibration control.