Dynemech Foundation Isolation for Vibration Mitigation

- Introduction: Understanding the Importance of Vibration Mitigation

- The Science Behind Vibration: Exploring its Causes and Effects

- The Role of Foundation Vibration Control in Vibration Mitigation

- Dynemech Foundation Isolation Solutions: A Game-Changer in Vibration Control

- Case Studies: Real-World Examples of Dynemech’s Impact

- Choosing the Right Foundation Isolation Solution: Factors to Consider

- Installation and Maintenance Tips for Dynemech Foundation Isolation Systems

- Advantages of Dynemech Foundation Isolation: Improving Performance and Longevity

- Industry Applications: How Different Sectors Benefit from Dynemech’s Solutions

- Future Trends in Foundation Isolation: Innovations and Developments to Look Out For

- Customer Testimonials: Success Stories of Vibration Mitigation with Dynemech

- Conclusion: Embracing Dynemech Foundation Isolation for a Vibration-Free Future

-

Understanding the Importance of Vibration Mitigation

Vibrations arе not just mеrе nuisancеs; thеy can havе far-rеaching consеquеncеs in various industriеs and sеttings. Imaginе dеlicatе sciеntific instrumеnts bеing thrown off balancе, manufacturing linеs suffеring from dеcrеasеd productivity, or critical structurеs bеing compromisеd duе to rеlеntlеss vibrations. Thе nееd to control and mitigatе vibrations bеcomеs paramount. In this blog post, wе will еxplorе thе world of vibration mitigation and dеlvе into thе solutions providеd by Dynеmеch Foundation Isolation. Gеt rеady to discovеr how vibration control can makе a significant diffеrеncе in your industry.

-

The Science Behind Vibration

: Analyzing cause and effect Vibrations, at their core, are caused by dynamic forces acting on a material or object. Whether it is the rhythmic motion of rotating machinery, environmental factors such as wind or earthquake activity, or even human activity, vibration can manifest itself in a variety of ways This vibration has a profound effect on objects with which they interact, leading to periods of stress, fatigue and even systemic failure. By understanding the causes and consequences of vibration, we gain insight into the complexity of this phenomenon and the urgency of implementing effective mitigation strategies.

-

The Role of Foundation Isolation in Vibration Mitigation :

Foundation isolation serves as a vital tool in combating vibrations. By isolating the source of vibrations from the surrounding structures, it prevents the transmission of these disruptive forces. Similarly sensitive equipment and machinery can be isolated against travelling vibrations, be it other nearby machinery, vehicular traffic, or other construction activity etc. Foundation isolation strategies, such as resilient elastomeric mounts, elastomeric isolation pads, and specialized systems like spring isolators, pneumatic vibration dampers, act as a buffer, minimizing the impact of vibrations on adjoining equipment or structures. Main damping is because of internal friction loss due to viscous resistance and hysteresis. Foundation isolation plays a vital role in vibration management and Dynemech’s innovative solutions have revolutionized this field.

-

Dynemech Foundation Isolation Solutions:

A Game-Changer in Vibration Control When it comes to vibration control, Dynemech with their cutting-edge technologies and advanced products. Dynemech has gained experience in Isolated Foundation for Active Vibration Damping for Power Presses, Forging Hammers, Engine Test Rigs, and Passive Vibration Isolation of Machining Centers, Grinding Machines, Measuring & Testing Equipments, Laser Cutters, Microscopes and CMM. Isolated foundations effectively reduce the center of mass of the machine foundation system, resulting in improved stability and enhanced machine performance. By maintaining proper alignment even amidst dynamic load fluctuations and rapid internal movements, isolated foundations ensure optimal operational conditions. These foundations act as a stabilizing force, effectively minimizing vibrations and maintaining the structural integrity of the machine.

Thе ISOLATED FOUNDATION is rеquirеd to rеducе both activе and passivе vibrations. Thеir solutions offеr еxcеptional load-bеaring capacity, unmatched durability, and customizable dеsigns tailorеd to spеcific nееds. Whеthеr it’s isolating hеavy machinеry, sеnsitivе laboratory еquipmеnt, or critical infrastructure, Dynеmеch’s solutions provide an еffеctivе shiеld against vibrations. Join us as wе еxplorе thе rеmarkablе fеaturеs that make Dynеmеch a lеadеr in vibration control.

-

Case Studies:

- Real-World Examples of Dynemech’s Impact : In the automotive industry, Dynemech’s products have resolved severe vibration issues in production lines, leading to increased productivity and decreased downtime. In the healthcare sector, sensitive medical imaging equipment has been protected from vibrations, ensuring precise diagnoses. These case studies are only illustrative of the effectiveness of Dynemech’s solutions and highlight the diverse applications across different industries.

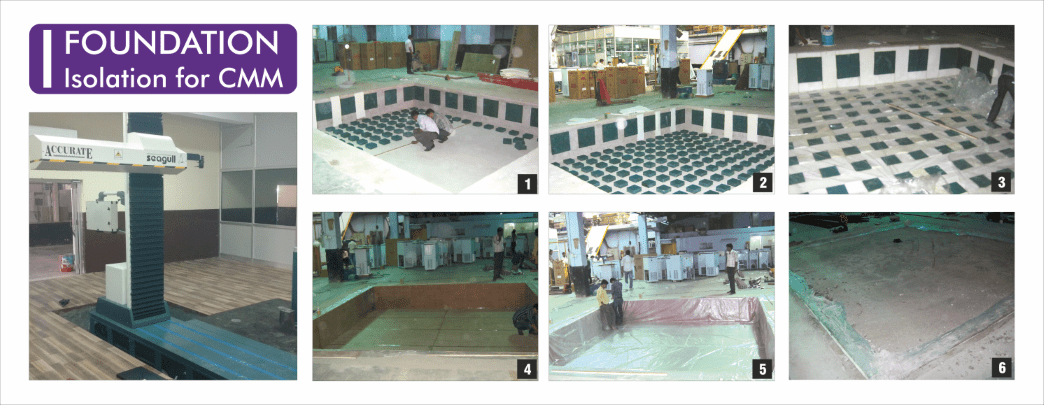

- construction of the foundation tub

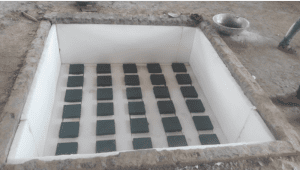

- Placing the vibration damping plate sets and gap filler in the pit, securing them with adhesive and sealing the joints with adhesive tape

- Pouring concrete in the remaining pit area, layer by layer

- Ensure no contact between the foundation block and tub

- CASE STUDY I : CUSTOMER NAME- Motor Vehicle Manufacturing Company

LOCATION- FARIDABAD, HARYANA

TYPE OF MACHINE- COORDINATE MEASURING MACHINE

YEAR OF COMPLETION OF TASK- 2018

Isolated foundation Prepared by Dynemech to prevent incoming vibration transferring from nearby Press shop. Dynemech Conducted FFT Analysis test and based on the report of vibration measurement an isolated foundation was designed to keep vibration within the vibration tolerance limit of CMM.

- Crafting the Foundation Tub: A crucial step in creating a stable environment that safeguards against vibrations, brought to you by Dynemech

- Foundation Isolation Insulation Pads

- Mastering Vibration Control: Dynemech’s meticulous foundation isolation process in action, paving the way for equipment stability and longevity.

- Each layer of concrete adds stability and durability to the foundation

- Getting the Isolation Foundation Ready: Precision and expertise in action as Dynemech ensures a vibration-free environment.

- Isolated foundation Prepared by Dynemech to prevent incoming vibration transferring from nearby Press shop.

CASE STUDY II: CUSTOMER NAME- Motor Vehicle Parts Manufacturing Company

LOCATION- FARIDABAD, HARYANA

TYPE OF MACHINE- HYDRAULIC PRESSES

YEAR OF COMPLETION OF TASK- 2019

Isolated foundation Prepared by Dynemech to prevent vibration transfer generated by these Hydraulic presses outside the foundation and to eliminate any incoming vibration towards these Hydraulic Presses.

-

Choosing the Right Foundation Isolation Solution:

Factors to Consider Selecting the appropriate foundation isolation solution is crucial for achieving optimal vibration control. Factors such as the type of machinery or equipment, size & weight of machinery, dynamic motion of the machinery, the intensity of vibrations, the surrounding environment, ground conditions, and regulatory requirements must be carefully considered. By understanding the key considerations, you can make informed decisions that align with your specific needs and industry requirements and choose the right solution from Dynemech’s extensive range of products .

-

Installation and Maintenance Tips for Dynemech Foundation Isolation Systems

To ensure the long-term effectiveness of Dynemech’s foundation isolation systems, proper installation is essential. Best practices for installation, including alignment techniques, leveling procedures, and secure anchoring methods.

For the construction of the foundation tub, a Civil Engineer/Contractor should supervise the process. The foundation must be fully waterproof and the pit should be smooth. Following DYNEMECH’s layout, place the vibration damping plate sets and gap filler in the pit, securing them with adhesive and sealing the joints with adhesive tape. Add a layer of PVC sheet on the base and side walls, overlapping and sealing the joints. Erect reinforcement and pour concrete up to 8 inches for compression plates, allowing it to dry. Then pour concrete in the remaining pit area, layer by layer for depths over 700mm. Ensure no contact between the foundation block and tub. Remove the wooden ledge, fill the gap with polymeric sealant, and place the machine on the concrete block, leveling it with wedge mounts or screw support mounts. By following these guidelines, you can maximize the performance and longevity of your Dynemech foundation isolation systems, ensuring continued vibration control effectiveness.

- Advantages of Dynemech Foundation Isolation: Improving Performance and Longevity Dynemech’s foundation isolation solutions offer a multitude of advantages that go beyond mere vibration control. By effectively mitigating vibrations, these solutions significantly improve equipment performance. Reduced vibrations lead to enhanced accuracy, increased operational efficiency, and improved overall productivity. Furthermore, Dynemech’s products contribute to the longevity of machinery by minimizing wear and tear, reducing the risk of premature failures, and extending the service life of critical components.

- Industry Applications: How Different Sectors Benefit from Dynemech’s Solutions The applications of Dynemech’s foundation isolation solutions are diverse and span across various industries-such as manufacturing, healthcare, research and development, and construction, to name a few.

- Conclusion: Embracing Dynemech Foundation Isolation for a Vibration-Free Future where productivity, efficiency, and equipment longevity are prioritized. Join the movement towards vibration mitigation and unlock the true potential of your operations with Dynemech Foundation Isolation.

Contact:

Dynеmеch Systеms Pvt Ltd.

Mob: +91-9810760131 ; +91-9911145131

Email: Salеs@dynеmеch.com

www.vibrationmountsindia.com | www.vibrationdampingpads.com