Introduction:

Machinery noise and vibration are due to the unwanted sound and motion of commercial machinery, mechanical systems, or equipment while they’re in use. Excessive vibration and noise can have several harmful effects. First of all, it may be uncomfortable and interrupt the workplace causing problems for them. Furthermore, excessive vibrations can result in mechanical wear and tear, raising the expense of machinery maintenance and repairs. There are several benefits of Anti-vibration mounting pads like they absorb and dampen machine vibrations. They successfully separate the equipment from the mounting surface, minimizing vibrational transfer to nearby buildings or the ground.

Obstacle: Machinery noise and vibration

To maintain optimal performance, worker safety, and regulatory compliance, it is essential to understand the underlying causes and impacts of these noises and vibrations. There are many different reasons for equipment noise and vibration. Common offenses include imbalance, misalignment, and worn or lost components. Vibrations and noise arise when spinning parts, such as rotors or shafts, are out of balance.

The ideal solution:

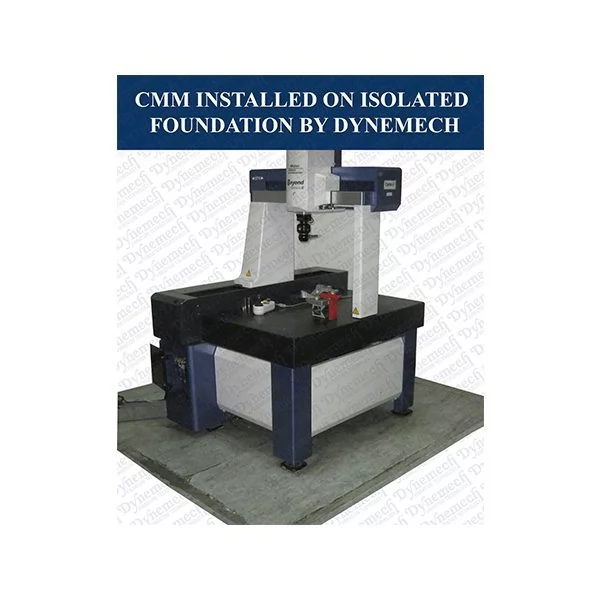

Anti-vibration mounting pads help to reduce vibrations and quieten machinery. These pads efficiently absorb and isolate vibrations and act as a barrier between the apparatus and its mounting surface.

Following are the different pads available with Dyenemech Vibration:-

Rubber Mounts:

Because of their outstanding vibration isolation qualities, rubber mounts come in use frequently. They constitute of metal plates or studs and a rubber element.

Cork Pads:

Made of compressed cork material, cork pads have strong vibration-dampening qualities. They are durable, lightweight, and effectively insulate against vibrations.

Spring Mounts:

Coil springs are used in spring mounts to insulate machinery from vibrations. These mounts have a great capacity for supporting loads and are of frequent use with large machinery and equipment.

Benefits of Anti-Vibration Mounting Pads:

They are many benefits of Anti-Vibration Mounting Pads. They first lessen vibrations, which reduces noise transmission and averts any harm to nearby structures. These pads save on maintenance and repair expenses while enhancing the performance, accuracy, and durability of equipment by absorbing vibrations. They increase operator comfort and safety by reducing the possibility of tiredness and health problems brought on by extended vibration exposure. In addition to being simple to install and versatile, anti-vibration mounting pads can support various machine types and weights. Overall, these pads provide optimal performance, equipment protection, and a quieter, more effective, and more productive working environment.

Improved performance and productivity:

The effectiveness and productivity of machinery and equipment can be significantly impacted by the use of anti-vibration pads. Here are some significant ways that these pads help to increase effectiveness:

Vibration Reduction:

Anti-vibration pads are an efficient way to separate equipment from its mounting surface. They do this not only by absorbing but also by dampening vibrations produced during operation. These pads reduce vibrations, resulting in a steady, vibration-free environment that enables machines to function more precisely and accurately.

Increased Equipment Lifespan:

Heavy vibrations can hasten the deterioration of mechanical parts, requiring more frequent maintenance and downtime. By absorbing vibrations and lowering stress on important components, anti-vibration pads assist in protecting equipment.

Conclusion:

Implementing anti-vibration measures reveals a dedication to worker safety and legal compliance. The long-term success of operations is ensured by investing in anti-vibration solutions, while also increasing productivity, lower maintenance costs, and limiting the detrimental impacts of vibrations. The workplace will be more productive and peaceful tomorrow if action is taken now.